![]()

- ■Can be used for various bolts, sizes and shapes of different reinforced steels.

- ■Used extensively for concrete, brick, stone material and hollow base material.

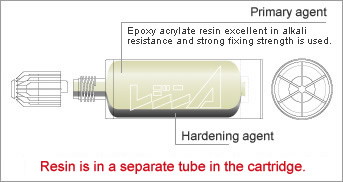

- ■Demonstrates stable fixing strength because primary material and hardening agent are constantly mixed by mixing nozzle.

- ■Adopts a highly alkali resistant epoxy acrylate resin.

<Code>

GE-165

(180*50*250)

Uses

Concrete•Stone material•Hollow base material•ALC

- Drill vertically to target surface with the determined preparation diameter and preparation hole depth.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Remove chips adhered in the hole using a brush, and use a dust collector or blower to clean in the hole again.

- Insert the nozzle down to the hole bottom and fill resin.

- Insert the bolt down to the hole bottom while slowly turning it by hand.

- Do not move the anchor bolt within the determined hardening time after embedding.

■Installation explanatory video

■Uses

Foundation work for iron frame, Passage construction work, Tunnel construction work, Installation for vibrating machines.

■Structural Drawing

■Installation specifications

| Nominal diameter(mm) |

M8 | M10 | M12 | M16 | M20 | M22 | M24 |

|---|---|---|---|---|---|---|---|

| Preparation hole diameter(mm) |

10.0 | 12.0 | 14.0 | 18.0 | 24.0 | 25.0 | 28.0 |

| Embedment depth(mm) |

80 | 90 | 110 | 130 | 170 | 190 | 210 |

| Required resin amount(ml) |

4 | 6 | 9 | 15 | 42 | 43 | 66 |

| Recommended tightening torque(Nm) |

10 | 20 | 40 | 80 | 120 | 140 | 160 |

| Number of pieces installed(Pcs) |

31 | 21 | 13 | 8 | 2 | 2 | 1 |

*The number of pieces installed indicates the target number taking into consideration a loss rate of 20%.

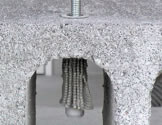

■Installation Example

■Shape of bolt used

Cannot be used for a round bar. Use bolts which have irregularity on a surface such as a continuous thread bolt and different shape bar steel.

■Guideline for hardening time

| Temperature(℃) | -5 | 5 | 15 | 25 | 35 |

|---|---|---|---|---|---|

| Use time(minutes) | 40 | 20 | 9 | 5 | 3 |

| Hardening time(minutes) | 180 | 90 | 60 | 30 | 20 |

(Do not move the anchor reinforcement within the hardening time.)

■Plastic sleeve installation specifications

| Nominal diameter(mm) |

M8 | M10 | M12 |

|---|---|---|---|

| Preparation hole diameter(mm) |

16.0 | 16.0 | 20.0 |

| Matching sleeve(Code) |

RA-P1685 | RA-P1685 | RA-P2085 |

| Required resin amount(ml) |

30 | 30 | 40 |

- Avoid direct sunlight and store in a well-ventilated place where the temperature does not rise so high.

(Never raise the temperature above 40℃. Always keep the temperature in the range of 5 to 25℃.) - Do not bring close to fire or high temperature objects.

- Cartridge can be stored until the expiration date for use under standard storage conditions.

- Wear protective equipment (such as protective glasses and mask) when using.

- When resin adheres to skin, irritation may occur in rare cases. Take action such as immediately wiping and rinsing with a hot soapy solution.

In addition, if resin gets into eyes, immediately rinse with a large amount of water and seek medical attention.

- Make sure to provide the drilling diameter and drilling depth as described in the specifications.

- Make sure to use both a metallic brush and blower to sufficiently clean inside the hole.

- Make sure to mount the mixing nozzle with it just before use.

- Make sure to discard first approximately 20~30cc at a time of first use and nozzle replacement. (Mixing improperly may result in reduction in strength.)

- This cannot be used for a steel bar with no irregularity such as a round bar.

- Refer to the scale on the cartridge label for discharge resin amount.

- Do not move the bar steel nor apply load within the determined hardening time.

| Size | Capacity(ml) | Content(Pc.) | JAN Code | |

|---|---|---|---|---|

| GE-165 | 165 | GE-165 Cartridge*1 Mixing nozzle*2 | 4989270930377 | |

| Product name | Size | Matching cartridge | JAN Code | Appearance |

|---|---|---|---|---|

| Mixing nozzle(3 Pcs.) | RA-MX3 | GE | 4989270930179 | |

| Injection gun 165 | RA-GUN165 | GE-165 | 4989270930247 |  |

| Use bolt different shape reinforced steel |

Preparation hole diameter (mm) |

Embedment depth (mm) |

Recommended tightening torque (Nm) |

Required resin amount (ml) |

Max. extraction strength (KN) |

Number of pieces installed (Pcs.) |

|---|---|---|---|---|---|---|

| M8 | 10.0 | 80 | 10 | 4 | 20.3 | 31 |

| M10 | 12.0 | 90 | 20 | 6 | 36.4 | 21 |

| D10 | 13.0 | - | 7 | 33.6 | 18 | |

| M12 | 14.0 | 110 | 40 | 9 | 42.5 | 13 |

| D13 | 15.0 | - | 7 | 62.4 | 18 | |

| M16 | 18.0 | 130 | 80 | 15 | 78.2 | 8 |

| D16 | 20.0 | - | 17 | 88.5 | 6 | |

| M20 | 24.0 | 170 | 120 | 42 | 125.3 | 2 |

| D19 | 25.0 | - | 42 | 146.7 | 3 | |

| M22 | 25.0 | 190 | 140 | 43 | 144.5 | 2 |

| D22 | 28.0 | - | 52 | 167.3 | 2 | |

| M24 | 28.0 | 210 | 160 | 66 | 167.7 | 1 |

| D25 | 32.0 | - | 75 | 208.2 | 1 | |

| M30 | 35.0 | 280 | 200 | 135 | - | 0 |

| D29 | 38.0 | - | 165 | - | 0 |

- *FC=21N/mm2

GE-165 TOOL BOX SET

| Product name | Content(Pc.) | JAN Code | |

|---|---|---|---|

| TB-165D(with drill) | GE-165*4 Injection gun 165*1 SDS Plus UX (12.0X160/14.0X210)*each 1 |

4989270930407 | |

| Standard set product | Mixing nozzle*6 Plastic sleeve 1685*5 Push pump*1 Metal brush(10/13/18) each 1 | ||

■Related items

| Size | Specifications | JAN Code | Appearance |

|---|---|---|---|

| RA-PUP | (Nozzle diameter) 10mm (Hose length) 270mm |

4989270930162 |  |

| Size | Specifications | JAN Code | Appearance |

|---|---|---|---|

| RA-MB10 | Φ10*300 | 4989270930292 |  |

| RA-MB13 | Φ13*300 | 4989270930193 | |

| RA-MB18 | Φ18*300 | 4989270930209 | |

| RA-MB28 | Φ28*300 | 4989270930216 |

| Size | Specification | JAN Code | Appearance |

|---|---|---|---|

| RA-EXP3 | Φ8×1m | 4989270930445 |  |

| Size | Specifications | JAN Code | Appearance |

|---|---|---|---|

| RA-P1685 | 16*85(M8/10) | 4989270930599 |  |

| RA-P2085 | 20*85(M12) | 4989270930261 |