![]()

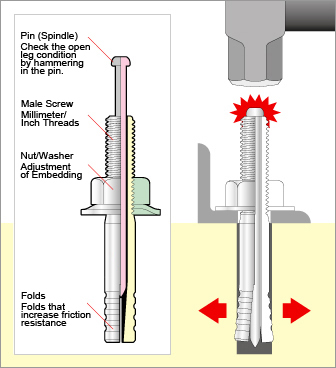

- ■Simply hammer in the pin. Just by looking at the pin, completion of an anchor can be confirmed.

- ■Screw diameter and anchor unit diameter are the same, allowing for drilling after installation of equipment and anchoring without rattle.

- ■The C-D type is dip-brazed, which is excellent in corrosion resistance.

| Thread dia | Tightening Torque |

|---|---|

| M6 | 5 N・m |

| M8 | 12 N・m |

| M10 | 24 N・m |

| M12 | 42 N・m |

| M16 | 100 N・m |

| M20 | 200 N・m |

- Drill a hole of a determined preparation hole diameter and depth from above the base material.

- Remove chips by dust collector or blower.

- Set the anchor and strike the pin with a hammer or the like.

- Tighten the nut with a spanner to complete the work.

■Installation explanatory video

■Uses

Suited for all kinds of fixture attachments including construction, electrical, sanitation, air conditioning / sign board attachment, seat attachment, and machine installation works.

■Structural Drawing

■Use examples

- Protective clothing including safety glasses and helmets must always be worn when installing.

- Drill perpendicularly into target surface.

- Compared with anchor insertion depth, drill holes should be 5mm deeper for M6, M8, M10; 7mm deeper for M12; 10mm deeper for M16; 15mm deeper for M20.

- Drilling preparation holes to shallow will break or bend a spindle.

- Sufficiently use blower.

- Always set nut before hammering.

- Use a hammer appropriate for the anchor size.

| Size | Dia (Outside diameter) |

Overall length (mm) |

Thread length (mm) |

Max. Use Thickness (mm) |

Drilling condition (mm) |

Embedment depth (mm) |

Max. extraction strength (kN) |

Pcs. /box |

Pcs. /ctn. |

JAN Code | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Preparation hole diameter |

Penetration hole depth |

||||||||||

| C-850D | M8 | 50 | 20 | 5 | 8.5 | 40 or more | 35 or more | 10.5 | 50 | 800 | 4989270701045 | C-870D | 70 | 25 | 25 | 50 | 400 | 4989270701052 |

| C-1050D | M10 | 50 | 20 | 5 | 10.5 | 35 or more | 30 or more | 12.6 | 50 | 400 | 4989270701106 |

| C-1060D | 60 | 25 | 5 | 45 or more | 40 or more | 15.1 | 50 | 400 | 4989270701113 | ||

| C-1080D | 80 | 25 | 25 | 50 | 300 | 4989270701120 | |||||

| C-1090D | 90 | 30 | 35 | 50 | 300 | 4989270701137 | |||||

| C-1010D | 100 | 30 | 45 | 50 | 300 | 4989270701144 | |||||

| C-1012D | 120 | 30 | 65 | 50 | 200 | 4989270701151 | |||||

| C-1260D | M12 | 60 | 25 | 8 | 12.7 | 42 or more | 35 or more | 17.3 | 30 | 240 | 4989270701182 |

| C-1270D | 70 | 25 | 8 | 52 or more | 45 or more | 19.7 | 30 | 240 | 4989270701199 | ||

| C-1290D | 90 | 30 | 28 | 30 | 180 | 4989270701205 | |||||

| C-1210D | 100 | 40 | 38 | 30 | 180 | 4989270701212 | |||||

| C-1212D | 120 | 50 | 58 | 30 | 120 | 4989270701229 | |||||

| C-1215D | 150 | 50 | 88 | 30 | 120 | 4989270701236 | |||||

| C-1610D | M16 | 100 | 40 | 18 | 17.0 | 70 or more | 60 or more | 40.1 | 15 | 90 | 4989270701250 |

| C-1612D | 120 | 40 | 38 | 15 | 90 | 4989270701267 | |||||

| C-1615D | 150 | 40 | 68 | 15 | 60 | 4989270701274 | |||||

| C-1619D | 190 | 50 | 108 | 15 | 60 | 4989270701281 | |||||

| C-2013D | M20 | 130 | 50 | 25 | 21.5 | 95 or more | 80 or more | 63.0 | 10 | 40 | 4989270701304 |

| C-2015D | 150 | 50 | 45 | 10 | 40 | 4989270701311 | |||||

*Maximum extraction strength values are values measured by UNIKA and not standard values.