![]()

- ■T.C.T. hole saw standard type.

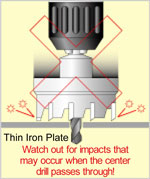

- ■Adopting the step center drill dampens impacts that occur when the center drill passes through.

- ■Adopting the “10 mm/13 mm chuck combination shank,” allows for most drill chuck diameters.

![]() Cannot be used with drilling machines.

Cannot be used with drilling machines.

◆Effective length: 4.5mm(Throat depth: 12 mm)

◆Matching drill: Electric drill/Percussion drill(rotating mode)

◇Ejector spring up to 53 fitted as standard/compatible with stainless steel

<Gauge>

14-30mm

(50*30*116)

<Gauge>

31-40mm

(62*43*116)

<Gauge>

41-55mm

(75*56*116)

<Gauge>

56-80mm

(110*86*140)

<Gauge>

85-120mm

(150*126*140)

*Numerical values in ( ) indicate the package size. W × D × H (mm).

The size dimensions have an error of approximately 2mm depending on the package.

■Performance is achieved in the following cases:

Pull Box

(t = 2 mm)

Stainless Steel Plate

(t = 1 mm)

Aluminum Square Pillar

(t = 1 mm)

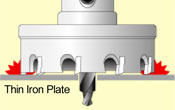

■Drilling swarf discharge groove

Drilling swarf is efficiently discharged through these drilling swarf discharge grooves to the peripheral side. Clogging of drilling swarf between the work material and cutting edge makes drilling impossible, which leads to tips cracking and chipping.

■Specially ground cutting edge

Cutting resistance is significantly reduced by specifically grinding the tungsten carbide/ultra-hard tip of the cutting edge.

■Newly developed step center drill

Two-step structure of the center drill tip end dampens impacts that occur when the center drill passes through, preventing cracking of the tungsten carbide/ultra-hard tip.

■10 mm/13 mm chuck combination shank?Eallows for most drill chuck diameters.

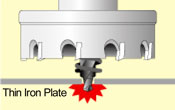

■Function of step center drill (PAT.P)

The step center drill protects the tungsten carbide/ultra-hard tip of the cutting edge from impacts that occur when the center drill passes through, preventing cracking of the tip.

When the center drill passes through the work material, the stepped portion dampens impacts.

The tungsten carbide/ultra-hard tip of the hole saw starts drilling the work material.

■Appropriate Rotation Speed

- ■Use the drill at a rotation speed appropriate for the drilling work material and diameter.

- ■Select a lower rotation speed for continuous cutting.

■Peripheral Speed

| Stainless Steel | Common Steel | Aluminum |

|---|---|---|

| 25-35 m/min | 40-60 m/min | 60-100 m/min |

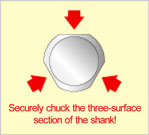

- Securely chuck the three-surface section of the shank to prevent swinging or falling.

- Do not hit the cutting edges of the tungsten carbide/ultra-hard tip against any hard object or allow strong contact with the work material that may occur when the center drill passes through. The tip will crack.

- Do not reduce the rotation speed excessively during drilling. Jamming or tip cracking may result.

| Size | Diameter(mm) | Overall Length(mm) | Effective Length(mm) | Shank Dia(mm) | Pcs./box | JAN Code |

|---|---|---|---|---|---|---|

| MCS-14 | 14 | 79 | 4.5 | 10/13 | 5 | 4989270510043 |

| MCS-15 | 15 | 4989270510050 | ||||

| MCS-16 | 16 | 4989270510067 | ||||

| MCS-17 | 17 | 4989270510074 | ||||

| MCS-18 | 18 | 4989270510081 | ||||

| MCS-19 | 19 | 4989270510098 | ||||

| MCS-20 | 20 | 4989270510104 | ||||

| MCS-21 | 21 | 4989270510111 | ||||

| MCS-22 | 22 | 4989270510128 | ||||

| MCS-23 | 23 | 4989270510135 | ||||

| MCS-24 | 24 | 4989270510142 | ||||

| MCS-25 | 25 | 4989270510159 | ||||

| MCS-26 | 26 | 4989270510166 | ||||

| MCS-27 | 27 | 4989270510173 | ||||

| MCS-28 | 28 | 4989270510180 | ||||

| MCS-29 | 29 | 4989270510197 | ||||

| MCS-30 | 30 | 4989270510203 | ||||

| MCS-31 | 31 | 79 | 4.5 | 10/13 | 3 | 4989270510210 |

| MCS-32 | 32 | 4989270510227 | ||||

| MCS-33 | 33 | 4989270510234 | ||||

| MCS-34 | 34 | 4989270510241 | ||||

| MCS-35 | 35 | 4989270510258 | ||||

| MCS-36 | 36 | 84 | 4.5 | 10/13 | 3 | 4989270510265 |

| MCS-37 | 37 | 4989270510272 | ||||

| MCS-38 | 38 | 4989270510289 | ||||

| MCS-39 | 39 | 4989270510296 | ||||

| MCS-40 | 40 | 4989270510302 | ||||

| MCS-41 | 41 | 84 | 4.5 | 10/13 | 3 | 4989270510319 |

| MCS-42 | 42 | 4989270510326 | ||||

| MCS-43 | 43 | 4989270510333 | ||||

| MCS-44 | 44 | 4989270510340 | ||||

| MCS-45 | 45 | 4989270510357 | ||||

| MCS-46 | 46 | 4989270510364 | ||||

| MCS-47 | 47 | 4989270510371 | ||||

| MCS-48 | 48 | 4989270510388 | ||||

| MCS-49 | 49 | 4989270510395 | ||||

| MCS-50 | 50 | 4989270510401 | ||||

| MCS-51 | 51 | 4989270510418 | ||||

| MCS-52 | 52 | 4989270510425 | ||||

| MCS-53 | 53 | 81 | 4.5 | 10/13 | 3 | 4989270510432 |

| MCS-54 | 54 | 4989270510449 | ||||

| MCS-55 | 55 | 4989270510456 | ||||

| Size | Diameter(mm) | Overall Length(mm) | Effective Length(mm) | Shank Dia(mm) | Pcs./box | JAN Code |

| MCS-56 | 56 | 81 | 4.5 | 10/13 | 1 | 4989270510463 |

| MCS-57 | 57 | 4989270510470 | ||||

| MCS-58 | 58 | 4989270510487 | ||||

| MCS-59 | 59 | 4989270510494 | ||||

| MCS-60 | 60 | 4989270510500 | ||||

| MCS-61 | 61 | 4989270510517 | ||||

| MCS-62 | 62 | 4989270510524 | ||||

| MCS-63 | 63 | 4989270510531 | ||||

| MCS-64 | 64 | 4989270510548 | ||||

| MCS-65 | 65 | 4989270510555 | ||||

| MCS-70 | 70 | 4989270510562 | ||||

| MCS-75 | 75 | 4989270510579 | ||||

| MCS-80 | 80 | 4989270510586 | ||||

| MCS-85 | 85 | 81 | 4.5 | 10/13 | 1 | 4989270510593 |

| MCS-90 | 90 | 4989270510609 | ||||

| MCS-95 | 95 | 4989270510616 | ||||

| MCS-100 | 100 | 4989270510623 | ||||

| MCS-110 | 110 | 4989270510630 | ||||

| MCS-120 | 120 | 4989270510647 | ||||

| MCS-130 | 130 | 4989270510654 | ||||

| MCS-150 | 150 | 4989270510661 |

*Non-standard sizes can be specially manufactured to order. Inquire for conditions.

| Size | Diameter(mm) | Overall Length(mm) | Hole Saw Size(mm) | JAN Code |

|---|---|---|---|---|

| S-6SC | 6 | 47 | 14-150 | 4989270510678 |

*Use the S type (HSS drill/standard product) for metallic plate materials such as a stainless steel plate, steel plate and aluminum and synthetic resin plate.

| Size | Diameter(mm) | Overall Length(mm) | Hole Saw Size(mm) | JAN Code |

|---|---|---|---|---|

| T-6 | 6 | 47 | 14-150 | 4989270510029 |

*Use the T type (tungsten carbide/ultra-hard drill [option]) for metallic plate materials such as a porcelain enameled steel plate and FRP and synthetic resin plate.

| Size | Hole Saw Size(mm) | JAN Code |

|---|---|---|

| MCS KS-No.1 | 14-19 | 4989270512009 |

| MCS KS-No.2 | 20-150 | 4989270512016 |

TOOL BOX SET

| Size | Set Dia(mm) | JAN Code | |||||

|---|---|---|---|---|---|---|---|

| TB-04 | 22 | 28 | 30 | 32 | 38 | 50 | 4989270511002 |

| TB-05 | 21 | 21 | 27 | 27 | 33 | 33 | 4989270511019 |

| TB-06 | 20 | 22 | 28 | 32 | 35 | - | 4989270511026 |

| TB-07 | 21 | 27 | 33 | 42 | 53 | - | 4989270511057 |