- Normal Body

- Long Body

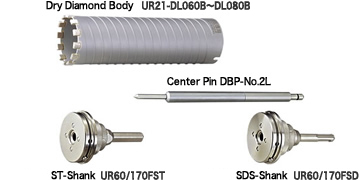

![]()

- ■Capable of drilling reinforced concrete(cutting up to triple-reinforcement), blocks, mortar etc. without the use of water.

- ■Center pin type cuts using only rotation force, greatly reducing noise of vibration.

- ■Long type with an effective length of 200 mm.

◆Applicable Electric Tool: Electric Drill / Percussion Drill (rotating mode)

*For porcelain ceramic tile and stone, water should be used.

Uses

REINFORCED CONCRETE•HARD EXTERIOR PANEL•Resin-based ARTIFICIAL MARBLE•MORTAR•

SOFT EXTERIOR PANEL•BLOCK•BRICK•*CERAMIC TILE

- ■Note that the cutting edge may experience wear sooner when used for concrete without the elapse of an insufficient curing period.

- ■Make sure to use the drill in the “rotation mode.” Using the drill in the percussion/impact mode may cause falling of the cutting edge or other failures.

- ■Note that forced insertion/removal operations during drilling (the cutting edge collides against the hole bottom or hole wall) or excessive tilting of a tool may also cause failures.

- ■Make sure to use this product in a “dry” condition. Using it in a wet or a damp condition may cause not only a shorter life but also reduced operating efficiency.

■Handling Method (Dry Diamond UR-D/DL [common])

![Handling Method (Dry Diamond UR-D/DL [common])](images/ur21d_dg1.gif)

- Align the center pin with the drilling position. Hold it tight and turn on the motor switch. [Rotation mode]

- Stop the motor when the cutting edge is inserted approximately 5 mm and remove the center pin.

- Lightly press the body against the drilling groove and continue operation.

■Dressing (sharpening) operation

Perform dressing (sharpening) operation in the following cases:

- ■Where cutting quality deteriorates during drilling

- ■Where burns or discoloration is detected on the cutting edge

In dressing operation, perform normal drilling in heavy weight (hollow) blocks or GC/WA grinding wheels. Dressing operation is completed when diamond particles protrude from the cutting edge surface and streaks in the rotation direction become clear.

| Code | Diameter (mm) |

Effective Length (mm) |

Center Pin (code) |

JAN Code | ||

|---|---|---|---|---|---|---|

| ST-Shank | SDS-Shank | ST | SDS | |||

| UR21-DL060ST | UR21-DL060SD | 60 | 200 | DBP-No.2L | 4989270262249 | 4989270263246 |

| UR21-DL065ST | UR21-DL065SD | 65 | 4989270262256 | 4989270263253 | ||

| UR21-DL070ST | UR21-DL070SD | 70 | 4989270262263 | 4989270263260 | ||

| UR21-DL075ST | UR21-DL075SD | 75 | 4989270262270 | 4989270263277 | ||

| UR21-DL080ST | UR21-DL080SD | 80 | 4989270262287 | 4989270263284 | ||

All replacement blades and all sizes (diameter: 60 - 170 mm) are available for one type shank assembly.

| Code | Diameter (mm) |

JAN Code |

|---|---|---|

| UR21-DL060B | 60 | 4989270267244 |

| UR21-DL065B | 65 | 4989270267251 |

| UR21-DL070B | 70 | 4989270267268 |

| UR21-DL075B | 75 | 4989270267275 |

| UR21-DL080B | 80 | 4989270267282 |

| Code | Overall Length (mm) |

Core Drill Size (mm) |

JAN Code |

|---|---|---|---|

| DBP-No.2L | 257 | 60-80 | 4989270220096 |

| Code | Core Drill Size (mm) |

JAN Code | ||

|---|---|---|---|---|

| ST-Shank | SDS-Shank | ST | SDS | |

| UR60/170FST | UR60/170FSD | 60-170 | 4989270225329 | 4989270225336 |