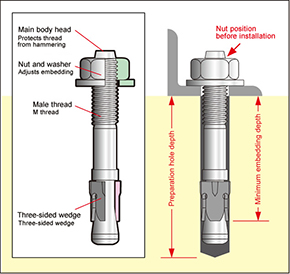

- ■Demonstrates reliable strength by installation through torque control and three-sided wedges.

- ■Demonstrates reliable installation strength with the torque control of the three-sided wedges. Installation can be done by either sides of the anchor as the diameter is the same.

- ■Overall length can be checked after installation by marking on the head.

- Drill vertically to target surface with the determined preparation diameter and preparation hole depth.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Insert a big one.

- Hammer in until the washer contacts the installed object.

- Use a torque wrench to tighten the nut to the specified torque value.

- The three-sided wedge expands and installation is completed.

- Wear safety protection equipment such as protective glasses, a helmet etc., during installation.

- Use a dust collector or blower to thoroughly remove chips in the hole.

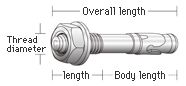

- Select overall length of anchor in consideration of thickness of installed object.

- Align the end face of the nut with the end of the tape to set.

- For installation, use a torque wrench to tighten to the specified torque.

■Uses

Electrical, plumbing, air-conditioning / heating duct works, elevator construction work, elevator installation work.

■Tightening torque

| Thread nominal diameter |

M8 | M10 | M12 | M16 |

|---|---|---|---|---|

| Width across flat |

13mm | 17mm | 19mm | 24mm |

| Tightening torque |

15N•m | 30N•m | 45N•m | 100N•m |

■Marking on head

| Overall length(mm) |

60 | 70 | 80 | 90 | 100 | 120 | 140 | 150 |

|---|---|---|---|---|---|---|---|---|

| Marking | B | C | D | E | F | H | J | K |

Before installation

Install it after aligning the nut with the taper end section on the head of the anchor body.

Installation check

If the thread section is protruded by a height of one nut or more when the nut is tightened, it has been improperly installed. Check the preparation hole diameter and install in another position.

| Size | Dia (outside diameter) |

L (mm) |

Marking on head |

TL (mm) |

Max. use thickness (mm) |

Drilling condition(mm) |

Nut width across flat (mm) |

Embedment depth(mm) |

Max. extraction strength (kN) |

Pcs./box | Pcs./ctn | JAN Code | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Preparation hole diameter |

Preparation hole depth |

||||||||||||

| BG-860 | M8 | 60 | B | 25.0 | 5 | 8.0 | 52 or more | 13 | 43 or more | 10.2 | 50 | 400 | 4989270730014 |

| BG-870 | 70 | C | 35.0 | 15 | 50 | 400 | 4989270730083 | ||||||

| BG-1070 | M10 | 70 | C | 26.5 | 4 | 10.0 | 60 or more | 17 | 52 or more | 14.7 | 30 | 240 | 4989270730021 |

| BG-1080 | 80 | D | 36.5 | 13 | 30 | 240 | 4989270730090 | ||||||

| BG-1090 | 90 | E | 46.5 | 22 | 30 | 240 | 4989270730038 | ||||||

| BG-1010 | 100 | F | 56.5 | 32 | 30 | 180 | 4989270730106 | ||||||

| BG-1280 | M12 | 80 | D | 29.0 | 4 | 12.0 | 68 or more | 19 | 61 or more | 26.2 | 25 | 150 | 4989270730045 |

| BG-1290 | 90 | E | 39.0 | 12 | 25 | 150 | 4989270730113 | ||||||

| BG-1210 | 100 | F | 49.0 | 22 | 25 | 150 | 4989270730120 | ||||||

| BG-1212 | 120 | H | 69.0 | 42 | 25 | 100 | 4989270730137 | ||||||

| BG-1215 | 150 | K | 99.0 | 72 | 25 | 100 | 4989270730144 | ||||||

| BG-1612 | M16 | 120 | H | 59.0 | 25 | 16.0 | 80 or more | 24 | 71 or more | 34.0 | 10 | 60 | 4989270730151 |

| BG-1614 | 140 | J | 79.0 | 45 | 10 | 60 | 4989270730168 | ||||||

*Maximum extraction strength values are values measured by UNIKA and not standard values.

| Size | Dia (outside diameter) |

Overall length (mm) |

Marking on head |

Thread length (mm) |

Max. use thickness (mm) |

Drilling condition(mm) |

Nut width across flat (mm) |

Embedment depth(mm) |

Max. extraction strength (kN) |

Pcs./box | Pcs./ctn | JAN Code | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Preparation hole diameter |

Preparation hole depth |

||||||||||||

| BG-1080D | M10 | 80 | D | 36.5 | 13 | 10.0 | 60 or more | 17 | 52 or more | 19.2 | 30 | 240 | 4989270732018 |

| BG-1090D | 90 | E | 46.5 | 22 | 30 | 240 | 4989270732025 | ||||||

| BG-1290D | M12 | 90 | E | 39.0 | 12 | 12.0 | 68 or more | 19 | 61 or more | 25.6 | 25 | 150 | 4989270732032 |

| BG-1210D | 100 | F | 49.0 | 22 | 25 | 150 | 4989270732049 | ||||||

| BG-1212D | 120 | H | 69.0 | 42 | 25 | 100 | 4989270732056 | ||||||

| BG-1612D | M16 | 120 | H | 59.0 | 25 | 16.0 | 80 or more | 24 | 71 or more | 41.6 | 10 | 60 | 4989270732063 |

| Size | Matching anchor thread dia. |

Overall length(mm) | JAN Code |

|---|---|---|---|

| BG-SD | M8,M10,M12 | 160 | 4989270940031 |

| BG-16SD | M16 | 160 | 4989270940048 |

- Set a nut on the specified position before hammering.

- After hammering, make sure to tighten the nut with a torque wrench to the specified torque.

- It cannot be used for BGL type.

| Size | Thread diameter (outside diameter) |

Overall length(mm) | Width across flat (mm) |

Pcs./box | Pcs./ctn | JAN Code |

|---|---|---|---|---|---|---|

| NBG-3010M | W3/8*M10 | 40 | 14 | 50 | 400 | 4989270739017 |

| NBG-4012M | W1/2*M12 | 50 | 19 | 25 | 200 | 4989270739031 |

| Size | Thread diameter (outside diameter) |

Overall length(mm) | Width across flat (mm) |

Pcs./box | Pcs./ctn | JAN Code |

|---|---|---|---|---|---|---|

| NBGS-3010M | W3/8*M10 | 40 | 14 | 50 | 400 | 4989270739048 |

| NBGS-4012M | W1/2*M12 | 50 | 19 | 25 | 200 | 4989270739055 |